Note: This guide might be a helpful resource for LAGI 2020 Fly Ranch participating design teams. The multi-disciplinary design challenge is open for submissions through October 31, 2020. For more information see: https://lagi2020flyranch.org.

It sometimes feels like the construction industry is on geological time when it comes to its response to the climate crisis. High-embodied carbon building materials and carbon intense methods of construction are the incumbents and business as usual is not easily moved. We used to use the handy expression, “at a glacial pace,” but glaciers are moving pretty rapidly these days.

With the built environment contributing 40% of global carbon emissions, and the emissions embodied in the materials and construction of buildings contributing 11% of global emissions (about as much as all automobiles), it’s up to architects, landscape architects, and to artists and creatives of all kinds who are designing places and objects in places, whether temporary or permanent, to commit to doing no harm, and whenever possible contributing to regeneration and healing.

We are light years away from that right now.

Some of the most expensive and high profile projects on the boards in 2020 are aiming way too low on measures of sustainability. To stay on target with what science tells us we must do, every single development, building, work of art in public space, and landscape should be striving to achieve functional net-zero emissions and a payback on its embodied carbon over the long lifetime of the project.

There are significant barriers to the certification of new and innovative products by the International Code Council, and it is in the short-term interests of the real estate and construction industry lobby and professional organizations to slow-walk change.

Still, technology has advanced rapidly over the past few decades and is absolutely ready to be called on just as soon as legislation can be passed to promote its adoption. While policy is not moving quickly enough, there are already many success stories out there from companies who have pioneered the way forward to regenerative building materials.

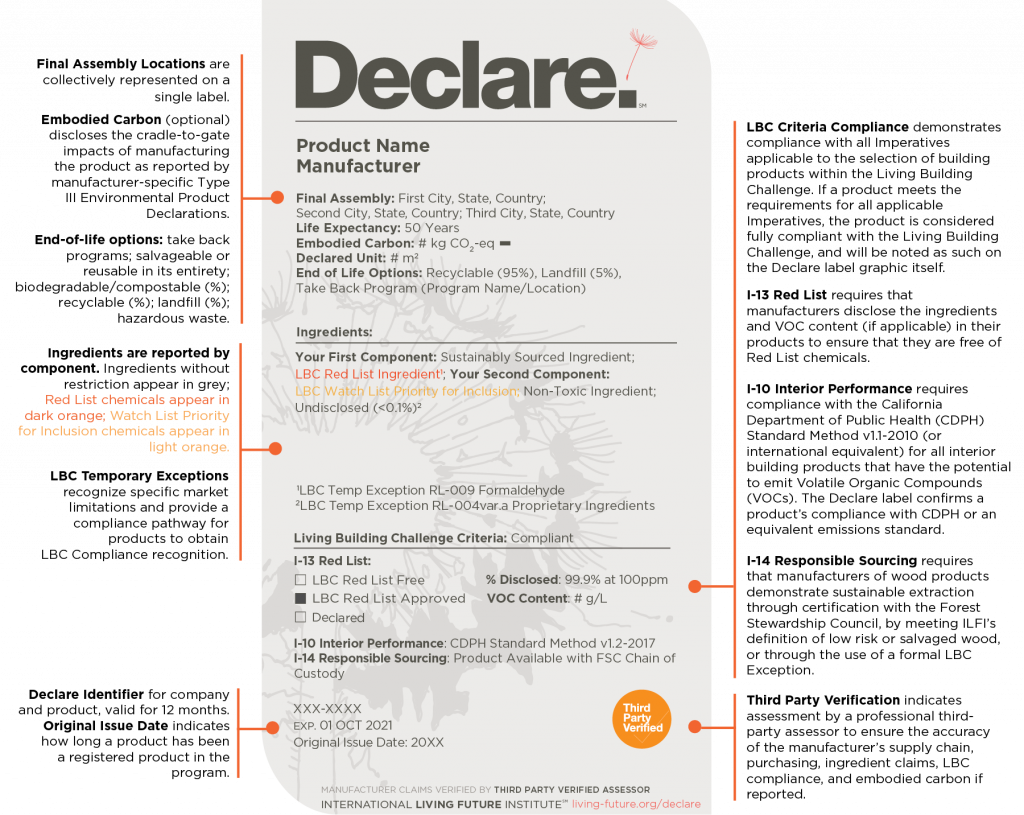

You’ll find many of these through the International Living Future Institute’s Declare program. ILFI also certifies products under their Living Product Challenge.

Materials

There are seven questions to ask when selecting building products for regenerative development.

- Embodied Carbon

How much carbon-based energy was consumed in the manufacture of the building product? Many building products require complex manufacturing processes, some of which require intense heat, most likely provided by a coal or gas furnace. When considered at the scale of a building or a development, embodied carbon includes the carbon emissions of the construction equipment, vehicles, deliveries, and construction waste streams as well as the embodied carbon in the materials themselves.Generally, you want to look for natural materials that don’t require a lot of processing, products that have a high percentage of easily recycled content, and materials that are sourced locally to minimize emissions from shipping. Using local soil for rammed earth walls is one example of a low-embodied carbon construction method.

- Sequestered Carbon

Does the building product itself contain CO2 within a rapidly renewable material? If so, then you can consider the material “regenerative” in the sense that it is contributing positively to a right-carbon future. Examples of this include fast-growing wood, hemp, bark, cork, straw, or bamboo, materials made from biochar, and mineralized CO2 within zero-carbon cement, gypsum, concrete that is removed or diverted from atmospheric emission, and that diverts otherwise harmful materials from landfills.Cross-laminated Timber (CLT) can replace steel as the structural material for most projects. It can be made using smaller understory trees, while leaving mature trees standing. Smaller caliper trees are faster to replace and the clearing of understory growth can contribute to healthy forest management and the prevention of wildfires.

- Ecological Footprint

Does the extraction and harvesting of the raw materials used in the product negatively impact the habitats and ecosystem of the region or contribute to deforestation? If so, what measures are being taken by the companies to mitigate the damage? The FSC standard has been around for a very long time. There is no excuse not to use FSC certified wood. - Active and Passive Energy

Does the material itself through its physical properties contribute to lowering the external energy & resource consumption of the building? These kind of materials and systems are referred to as “high-performance” because they serve to make the building more sustainable throughout its lifetime in its use of resources. Examples include building integrated photovoltaics (BIPV) like solar glazing and cladding, other clean-energy generating materials such as piezoelectric flooring, phase-changing materials, superinsulators, super efficient and integrated zero-emissions building systems, and energy storage within materials such as KPG concrete or MGA Thermal bricks. - Building Wellness

What is it like living in a space constructed of the materials? Do they off-gas volatile organic compounds? Do they cause allergic reactions or irritations? Do they promote healthy living? To learn more about this question see the Well Building Standard, and find products that are “red-list” free on the ILFI Declare site. Going a step further into regeneration are building materials, such as living walls and titanium dioxide surfaces that actually clean the air around them. - Life Cycle within the Circular Economy

Is the material designed for a lifetime of multiple generations? What happens to the product or material when it is at the end of its useful life? Is it easily recyclable using renewable energy resources? Does its decomposition release any dangerous chemical pollutants into soils and waterways?For the best practices in circular design, see the Ellen MacArthur Foundation’s resources, like the Circular Design Guide and worksheets, where you’ll discover building materials made from mushrooms, products with super long life cycles, and system innovations for the “maintenance” economy that can replace the “consumption” economy. Life-cycle of materials is also the focus of C2C product certification.

Here is also where resilience comes into play. The longer buildings last, the lower their ecological footprint over their life-cycle. We can design buildings in low-lying areas to passively flood without damage to finishes. We can design roof assemblies using masonry in high-risk wildfire areas. We can make every new development its own interconnected renewable energy microgrid that can withstand outages to power distribution lines.

- Support Thriving Communities

How does the manufacture and raw materials impact local economies? Does the entire process support jobs with living wages? Are companies in the supply chain good members of the local and global community? Here the strategy should be “buy local” whenever possible.

Construction

In terms of the means and methods of construction, companies like Nasta, Suncar, and ViridiParenti are selling battery-powered heavy equipment and hopefully companies like Caterpillar and John Deere will see the writing on the wall and kickstart their own energy transition. The world’s first zero-emissions construction site made the news this past April. Perhaps in the near future we will look back on that milestone the way we look back on the first transatlantic flight.

Advancements in battery powered tools and robotic equipment can be seen as another construction industry solution, and may also support affordable housing options. But they should be considered first through the lens of their impact on labor. 3D printing of entire buildings for example is certainly going to be a part of the future of construction.

If the construction industry is going to do its part to avert the worst effects of climate change, the timeline of the great building transition must pick up the pace and coincide with the great energy transition, which aims for 50% reduction in emissions by 2035 and zero emissions by 2050. Perhaps someday in the not-so-distant future our constructed environment will be in complete harmony with the natural world.

Related Posts

3 Comments

Add comment Cancel reply

This site uses Akismet to reduce spam. Learn how your comment data is processed.

COULD YOU PLEASE PROVIDE ME WITH THE REFERENCES USED TO ESTABLISH WHESE SEVEN QUESTION.? THANKS IN ADVANCE

Thank you for your comment. There are a number of links integrated into the article (red text). We recommend clicking on those links for more information.

The article highlights the urgent need for the construction industry to address climate change by adopting sustainable practices, especially considering the significant carbon emissions associated with the built environment. It emphasizes the role of architects, landscape architects, and creatives in pushing for regenerative building materials and methods. The importance of embodied carbon, sequestered carbon, ecological footprint, and energy efficiency in material selection is discussed. It calls for a rapid shift toward regenerative building practices and materials to combat the climate crisis effectively.